If you are a UK-based Haulier company, then you have already been faced with the exorbitant task of jumping legal hoops in order to ensure the safe passage of your product across land or sea. What you don’t need in addition to this, is to lose time and energy looking for the very best rotary vane vacuum pump suppliers, to sustain your company’s long-distance requirements. Being a frequent flier haulier means enormous potential wear and tear on your equipment through inferior product, or bad road handling techniques, which you cannot afford to have let you down at any stage along the journey. With customer demands and logistical costs to juggle, IBS takes pride in being able to offer, as part of its impressive bouquet of equipment, products that IBS can guarantee that you do not have to spend valuable time and energy worrying about.

IBS is the UK’s sole distributor of Fuitland RCF1200 Vacuum pump in Europe. A Canadian company with a long history of success which continues to grow from strength to strength, Fruitland equipment is well-known for requiring minimal maintenance as their products have been designed to deal with the harshest of liquid waste, using less oil than its competitors, and providing years of reliable service. IBS proudly partners with Fruitland vacuum pumps of all sizes, starting at the Fruitland RCF250 vacuum pump which is the smallest pump available, which is compact for circumstances where mounting space may be limited, through to the largest and most heavy duty of pumps, which is the Fruitland RCF1200 vacuum pump which is commonly found in use in the heavy duty and environmental applications.

Specifications are available on the IBS website and enquiries can be made by contacting and IBS product engineering expert. As an industry leader in the supply, reconditioning and maintenance of vacuums, pumps and blowers, IBS recognises the value of a hardworking, long wearing product and the impact that it can have on a business and choses products to match the ethos of IBS. Excellent workmanship, consistent production and formidable design is a minimal requirement for the standard of equipment that IBS relies on to enable our customers to safely bulk-haul dangerous and harsh products like oil, petroleum and gas. For customer convenience and versatility, IBS provides support to all vacuum truck specialists as well as their rental companies.

IBS offers the servicing, repair and reconditioning of road tanker equipment. Where a re-build is required, IBS ensures the use of genuine original parts. Road tanker equipment such as the Hydrive Series Hydraulic Cooler Packs, vital in the distribution of hazardous liquids where cooling or heat exchange is required, are brand leaders which IBS is able to supply. Technical specifications are also listed on the website but three important features which the Hydraulic cooler pack provides include: improved installation capability through compact sizing, ability to withstand harsh conditions due to use of stainless steel in construction and maintenance friendly features. Email your road tanker enquiry regarding repairs, servicing and reconditioning; spares and ancillaries or troubleshooting and an engineering expert will be in touch.

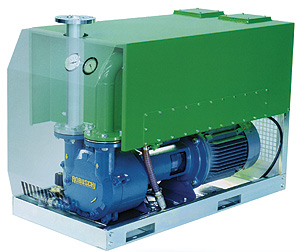

An example of Robuschi innovative tradition utilising a liquid ring vacuum unit in either oil or water versions which is:

An example of Robuschi innovative tradition utilising a liquid ring vacuum unit in either oil or water versions which is:

Vacuum pumps – the un-sung hero of home and industry – both practical and versatile all in one well designed piece of equipment. When it comes to pumps, vacuum pumps are utilised widely and are well respected in industry and retail simply due to their simple, practical form and countless functional aspects.

Vacuum pumps – the un-sung hero of home and industry – both practical and versatile all in one well designed piece of equipment. When it comes to pumps, vacuum pumps are utilised widely and are well respected in industry and retail simply due to their simple, practical form and countless functional aspects.